Let’s talk about this high-pressure magnetic drive pump thing. I spent some serious time working on this, and I figured I’d share what went down.

So, first off, I got my hands on this pump. It’s called a magnetic drive pump, basically no seals, which is pretty cool. I needed something that could handle high pressure without leaking all over the place, you know? This one promised to do the job, up to something like 2680 psi. That’s a lot of pressure!

I started by setting the whole thing up. Connected it to the system I was working with, making sure everything was tight and secure. No room for error when you’re dealing with this kind of pressure. It was a bit of a pain, honestly, getting all the connections just right, but I managed.

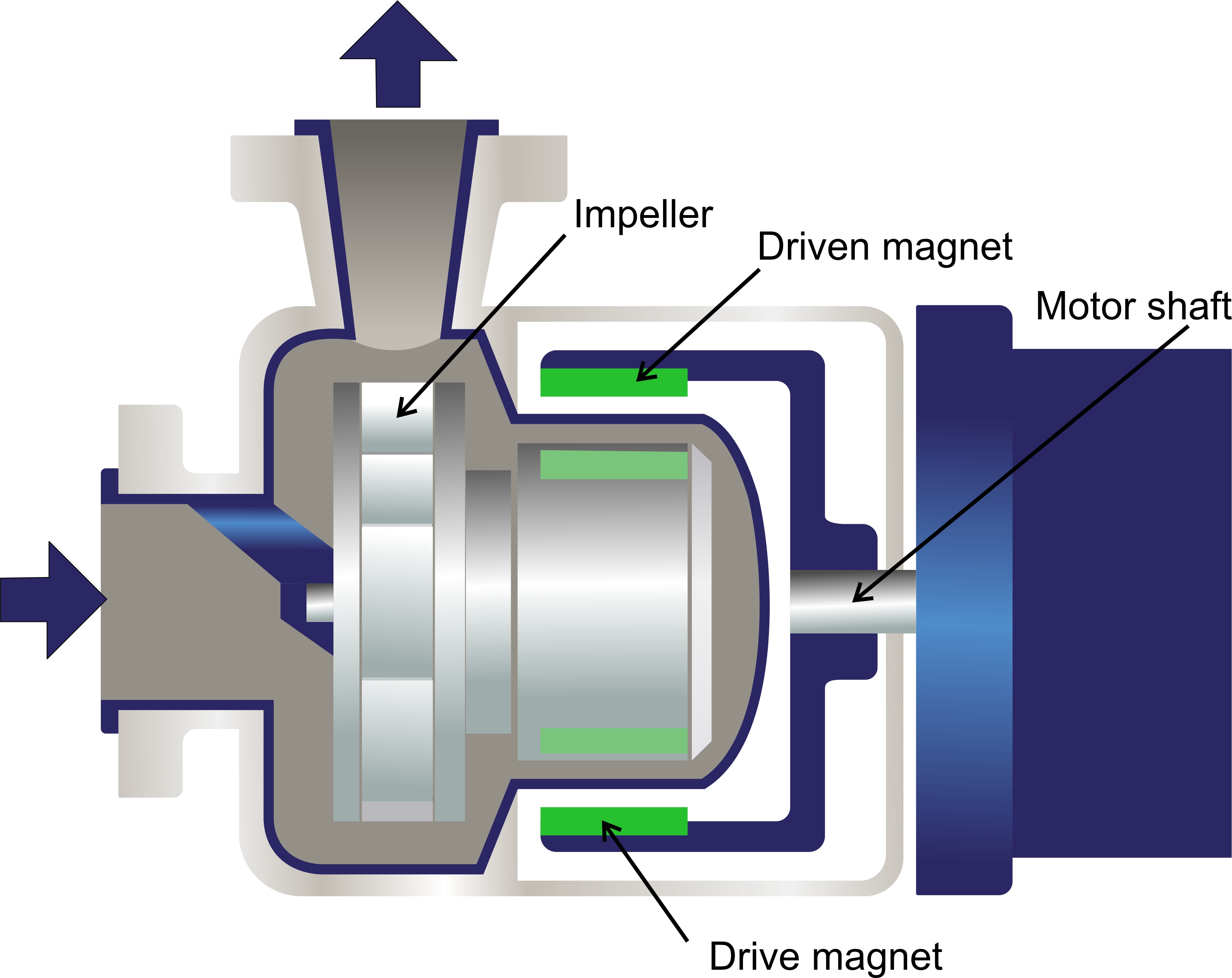

- Hooked up the motor. This is where the magic happens. The motor spins a magnet, and that magnet drives another magnet inside the pump. No direct connection, which is why it doesn’t leak.

- Filled the system with the fluid I was pumping. It was some kind of chemical, nothing too crazy, but still needed to be careful.

- Then I flipped the switch.

The pump whirred to life. You could feel the power. I watched the pressure gauge climb, and it went up, and up, and up. Past 1000 psi, past 2000 psi, all the way to that 2680 psi mark. And guess what? No leaks!

Success

I ran the pump for a while, just to make sure it was stable. It held that pressure like a champ. This thing is built like a tank. After a few hours, I shut it down. Job well done.

So yeah, that’s my story with the high-pressure magnetic drive pump. It was a bit of a challenge getting it all set up, but in the end, it worked exactly as advertised. If you need to move fluids at high pressure and can’t afford any leaks, this is the way to go. Just be prepared to spend some time getting those connections right.