Well now, let me tell you about these newfangled pumps, the magnetic drive pumps, or mag-drive pumps, as they like to call ’em. These pumps, they ain’t like the old ones you see at the factory or on farms. They got no shaft seals, no fancy little pots for seal fluids, and certainly no cooling lines to mess with. What they do have is magnets, big strong ones, that do all the work instead of the usual mechanical parts. Makes ’em cheaper to buy at first, and they ain’t so costly to run every day neither.

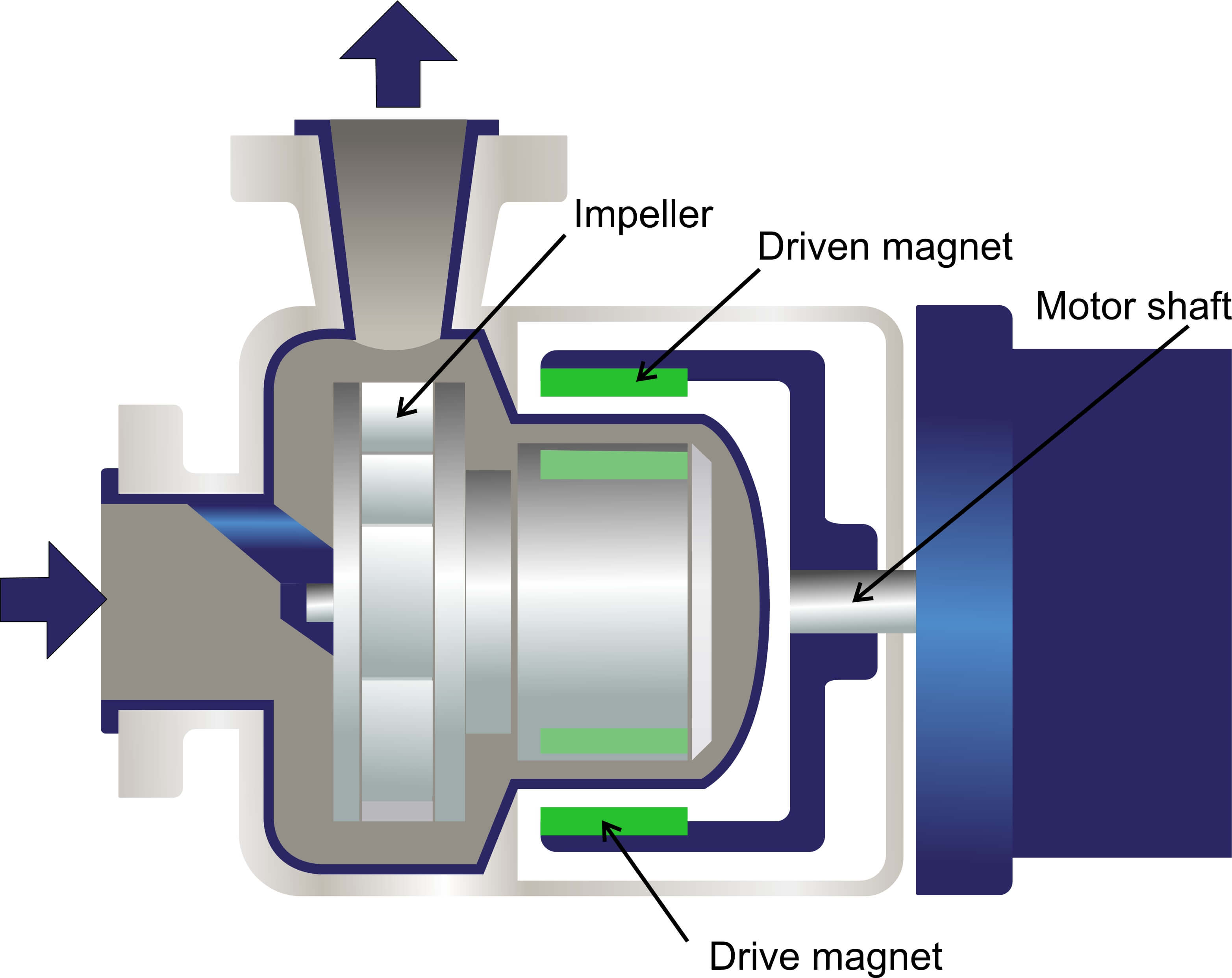

You see, this here magnetic drive pump uses two magnets. One’s outside, hooked up to the motor shaft, and the other one’s inside the pump, just sittin’ there all cozy-like. Now, these magnets, they ain’t touching each other, but they work together, you could say they got a little magnet magic going on. The outside magnet gets the inside one spinning, and that gets the liquid moving through the pump. All this happens without the motor and impeller ever actually touching. No friction, no wear and tear on parts that get too hot and burn out. It’s like magic, I tell ya!

But here’s the thing—these pumps need that liquid to keep things running smooth. The liquid’s gotta act like a lubricant and a coolant for the pump parts. If the pump runs dry, oh boy, that’s a real problem. The bearings, they can overheat something fierce, and other parts of the pump could get damaged too. And when that happens, you’re lookin’ at repairs or even a full replacement. So, these magnetic drive pumps ain’t the kind you want if you got a risk of runnin’ dry. It’s just one of them things you gotta watch out for.

Now, these pumps work a little different from your old-school centrifugal pumps. Those ones, they got a direct connection between the impeller and the motor, but not the mag-drive pumps. They use that magnetic field to get things spinning instead, which is a whole lot quieter and smoother, mind you. No noisy parts grinding together, just magnets doin’ their thing.

Magnetic drive pumps are often used in places where you need to move chemicals or other fluids that can’t be allowed to leak out. Since they don’t need seals, there’s less chance for leaks to happen. That’s why you’ll see ‘em in all kinds of industries, like chemical plants or even the food and beverage sector. Heck, they might even use ‘em in places like water treatment plants where they gotta keep things clean and leak-free.

Benefits of Magnetic Drive Pumps:

- Lower operational costs: Since they don’t need seals and all that fancy stuff, you don’t have to worry about maintenance as much.

- Safer operations: Less chance of leaks means you’re keepin’ things clean and safe, especially in places where hazardous fluids are used.

- No need for cooling lines: Because the liquid itself cools and lubricates the pump, you don’t need extra lines runnin’ all over the place.

Now, don’t go thinkin’ these pumps are perfect. They got their limits, like I said before, you gotta make sure they never run dry. And they ain’t the best for all kinds of fluids. They work best with liquids that are pretty stable and won’t burn up too quick if things get a little too hot. But if you know how to use ‘em right, these pumps can save you a whole lotta trouble.

Why choose a magnetic drive pump?

- They last longer than traditional pumps because there ain’t no seals to wear out.

- They’re more efficient, so you’ll use less energy compared to older types of pumps.

- They’re pretty much leak-proof, which is great when you’re dealing with dangerous liquids.

So, if you’re in the market for a pump that don’t need much fuss and can handle itself without a bunch of maintenance, you might wanna look into getting one of these magnetic drive pumps. They might just be the best thing you ever did for your operation.

Tags:[magnetic drive pumps, centrifugal pump, pump maintenance, chemical process pumps, leak-proof pumps, industrial pumps, pump repair]