Alright, so let me tell you about the time I messed around with this magnetic drive chemical pump. I was working on this project where we needed to move some pretty nasty chemicals around, and regular pumps just weren’t cutting it – leaks, corrosion, you name it. That’s when someone mentioned these mag drive pumps, and I thought, “Why not give it a shot?”

Getting Started

First thing I did was hit up a few suppliers. And man, there’s a lot of choices out there! Finally, I decided on this one model from a Japanese company. Seemed reliable, and apparently, they’ve sold like a million of these things worldwide. So, I figured they must be doing something right. I ordered one, and it showed up a few days later, all neatly packed and ready to go.

Setting It Up

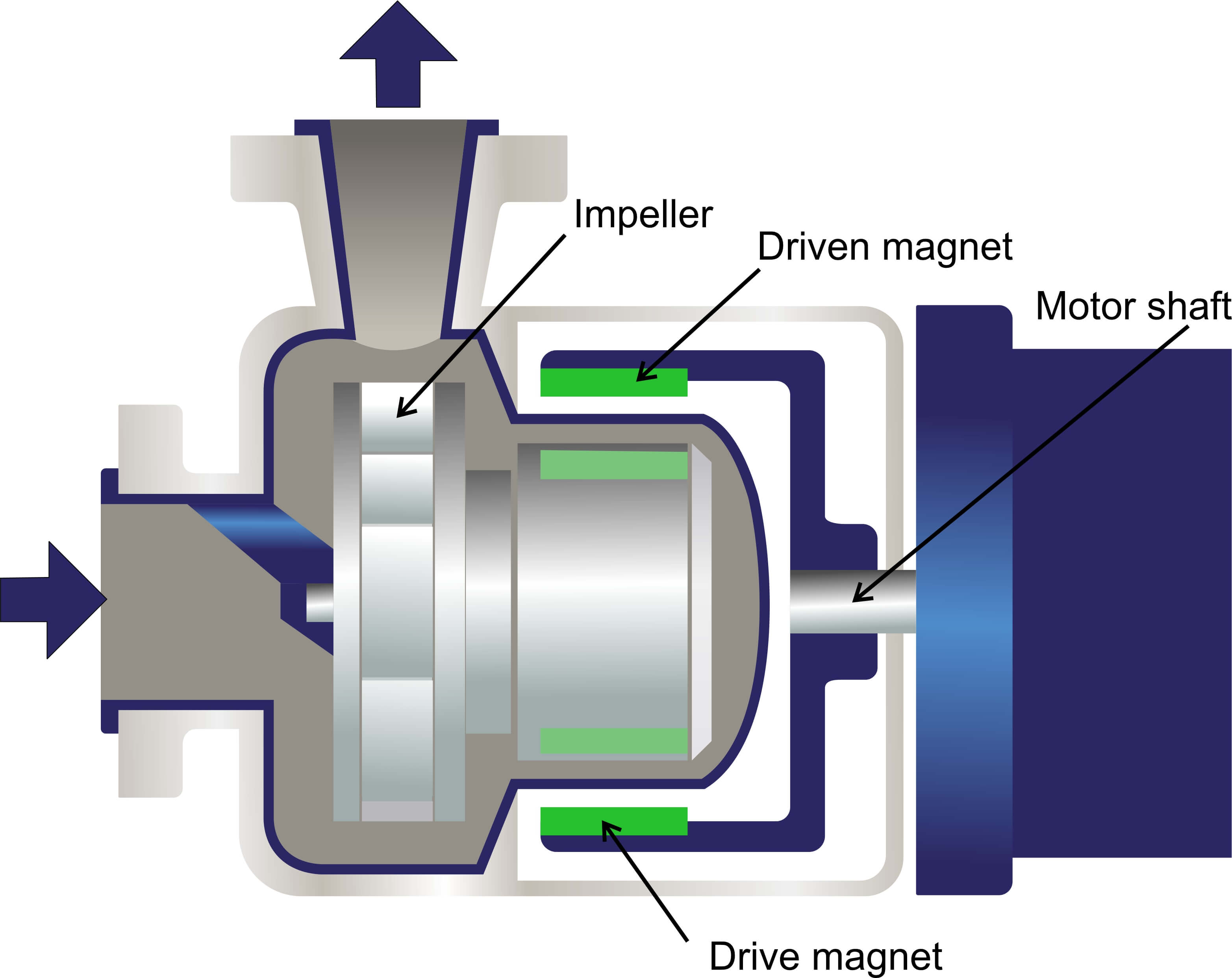

Getting this thing set up was a bit of a learning curve. I mean, I’ve worked with pumps before, but this one was different. No direct connection between the motor and the impeller, see? It’s all magnets doing the work. Kinda cool when you think about it. I hooked it up to the system, making sure all the pipes and connections were tight. We were dealing with some seriously corrosive stuff, so no room for error there.

The main things I had to worry about were dry running and overheating, as I recall. I also had to make sure nothing solid got into the pump, and watch out for these rapid pressure changes that can mess things up. No biggie, just stuff to keep an eye on, you know?

Putting It to the Test

Once everything was connected, it was time for the moment of truth. I flipped the switch, and that pump started humming. And let me tell you, it was smooth. No vibrations, no weird noises, just a steady flow of liquid. I monitored the pressure and flow rate, making sure everything was within the right range. And it was! This thing was moving those chemicals like a champ, no leaks, no fuss.

- Powering On: When I first turned it on, the AC power supply kicked in, changing the polarity on the coil.

- Magnet Action: This created a push-pull effect on the magnets.

- Diaphragm Movement: The magnets are connected to these diaphragms, so they started moving back and forth.

- Pumping Air: This motion caused the pump to suck in air and then push it out, over and over again.

It seemed that there were some other guys who had already used this kind of pump successfully. From the information, I knew that it had been sold well in over 50 countries around the world!

Long-Term Use

We ran that pump for months, and it didn’t skip a beat. We did regular checks, of course, just to make sure nothing was going wrong. I remember one time we thought we had a problem, but it turned out to be a clog in one of the lines, not the pump’s fault. Easy fix. Other than that, it was smooth sailing. I mean, compared to the old pumps we were using, this thing was a dream. Less maintenance, less downtime, and way less worrying about leaks.

Wrapping Up

So, that’s my story about the magnetic drive chemical pump. It was a bit of a gamble at first, but it totally paid off. I learned a lot, and it made our whole process so much safer and more efficient. If you’re dealing with tough chemicals and need a reliable pump, I’d definitely recommend looking into these mag drive things. They might seem a bit fancy at first, but trust me, they’re worth it. Just do your homework, pick the right one, and keep an eye on those pressure changes!