Well, let’s talk about this here thingamajig, the, uh, diaphragm pump for hydrochloric acid, yeah, that’s it. Don’t go lookin’ at me all confused, I know a thing or two, even if I ain’t no fancy engineer.

Now, this pump, it ain’t like them old well pumps we used to have, no sir. This one’s special, see? ‘Cause it’s gotta deal with that nasty hydrochloric acid stuff. That stuff eats through just about anything, so this pump’s gotta be tough. Real tough.

First thing you gotta know is what it’s made of. Can’t just use any ol’ metal, no way. This pump’s got a special casing, they call it, made outta somethin’ that acid can’t eat through. Like them fancy plastics, or maybe some metal that ain’t bothered by it. That’s the first line of defense, y’know? Like a good raincoat keepin’ ya dry in a storm. Hydrochloric acid transfer pumps have non-corrosive metal or plastic diaphragm pump casings to handle those mean old fluids, that’s what they say.

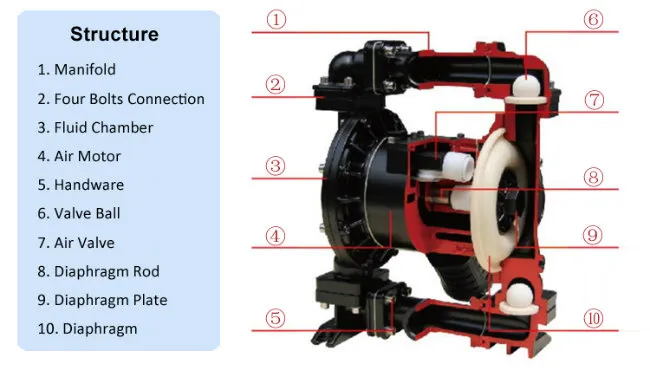

Then there’s the guts of the thing, the diaphragm. It’s like, well, it’s like a stretchy kinda thing that moves back and forth, pushin’ that acid along. Gotta be tough too, this diaphragm, ’cause that acid, it’ll try to chew through anything it can. So they make it outta special rubber or somethin’, somethin’ that can take a beatin’ and keep on pumpin’.

Now, usin’ this pump ain’t like turnin’ on a faucet, no sirree. You gotta be careful, real careful. After you’re done pumpin’ that acid, you gotta clean it out good. Flush the inside of the pump thoroughly with clean water, that’s what they say. Don’t leave no acid sittin’ in there, ’cause that’s when it starts eatin’ away at things. It’s like leavin’ dirty dishes in the sink, it just gets worse.

And them filters, gotta pay attention to them too. They catch all the junk, but if they get clogged up, well, that’s trouble. Special attention should be paid to rinsing the filters, as obstructions can cause serious damage. It’s like a clogged drain, nothin’ good comes from it. Clean ’em out good, make sure there ain’t no gunk blockin’ things up.

Keepin’ this pump runnin’ smooth ain’t just about cleanin’ it, though. It’s gotta be put in right, you know? Gotta have it all set up proper, otherwise it ain’t gonna work right. And you gotta keep an eye on it, make sure it’s doin’ its job. The proper operation of a diaphragm pump often depends on its proper installation and careful maintenance. Just like a tractor, you gotta take care of it or it’ll break down on ya.

- Check the pressure, make sure it ain’t too high or too low. Extreme Low or No Pressure: At times, that can be a problem.

- Listen to it, make sure it ain’t makin’ no funny noises.

- Keep it greased up, just like you would with any other machine.

If somethin’ ain’t right, you gotta fix it, and fix it quick. Don’t go lettin’ it sit there, gettin’ worse. A little problem can turn into a big problem if you don’t take care of it. It’s like a leaky roof, you fix it when it’s small, before it ruins the whole house.

So, there you have it, some things to know about this diaphragm pump for hydrochloric acid. It’s a tough piece of machinery, built to handle some nasty stuff, but it ain’t gonna last forever if you don’t take care of it. Proper maintenance is the cornerstone of extending the life and enhancing the performance of your manual diaphragm pump. Treat it right, and it’ll treat you right. By following these maintenance tips diligently, you’ll keep that pump hummin’ for a long time to come. Just like a good mule, you feed it, water it, and take care of it, and it’ll work for ya, day in and day out.

And remember, if you ain’t sure about somethin’, ask somebody who knows. Don’t go messin’ around with that acid stuff if you don’t know what you’re doin’. It ain’t worth gettin’ hurt. Safety first, always.

Anyways, that’s all I gotta say about that. Now, if you’ll excuse me, I gotta go check on my chickens.