Well, howdy there! Today, let’s gab a bit about them chemical feed pumps. You know, those things they use in factories and such. I ain’t no engineer, mind you, but I’ve seen enough contraptions in my day to know a thing or two.

First off, they also call ’em chemical dosing pumps, fancy names for somethin’ that just squirts stuff, if ya ask me. It’s like when you’re addin’ a pinch of salt to your cookin’, but on a much bigger scale. These pumps, they gotta be precise, ya know? Can’t just be dumpin’ stuff willy-nilly. It’s gotta be the right amount, every single time.

Now, from what I hear, these pumps are mighty important in all sorts of places. Factories, for sure. Places where they make food, too. Heck, even where they clean up water. Seems like everywhere you look, there’s one of these pumps doin’ its thing. They’re like the heart of the whole operation, keepin’ everything movin’ and groovin’.

- They use ’em in the chemical industry. That’s where they make all sorts of stuff, like them cleaners and whatnot.

- Then there’s the food industry. Gotta make sure everything’s safe and tasty, right? These pumps help with that.

- And don’t forget about water treatment. Gotta keep our water clean, and these pumps are part of that process, addin’ just the right amount of stuff to kill the germs.

One thing I heard about these pumps is that some of ’em are real good at suckin’ up stuff. They call it self-priming, or somethin’ like that. It means they don’t need a whole lot of fussin’ to get started. They just suck up the liquid and get to work. That’s mighty handy, especially when you’re dealin’ with nasty chemicals, like that stuff they use to clean pools, sodium hypochlorite, I think they call it.

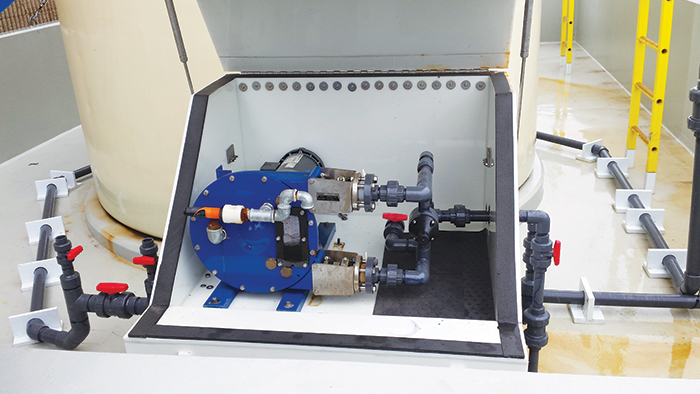

Now, these pumps ain’t just stand-alone things, ya know. They’re part of a whole system. Think of it like this: you got your pump, of course. Then you got a big ol’ tank to hold the chemicals. And then you got pipes connectin’ everything together. It’s like a big puzzle, and all the pieces gotta fit just right.

Positive displacement pump, that’s another fancy word they use. Means it pushes out a set amount of stuff each time it works. Like one of them old-timey water pumps, but way more precise. You know, the kind you gotta pump up and down to get water? Same idea, but these pumps do it all on their own, no arm-wrestling required!

And these pumps gotta be tough, too. They’re dealin’ with all sorts of chemicals, some of ’em pretty nasty. So, they gotta be made of strong stuff, somethin’ that won’t rust or break down. That’s why they use special materials, like stainless steel or somethin’. Gotta make sure they last a long time and don’t cause no trouble.

So, there you have it, a little bit about chemical feed pumps. They ain’t the prettiest things to look at, but they sure are important. They keep things runnin’ smooth and make sure everything’s just right. And that’s more than you can say for some folks I know!

Anyways, I hope that made some sense to ya. Like I said, I ain’t no expert, but I’ve been around long enough to pick up a thing or two. And if you ever see one of these pumps, you’ll know a little bit about what it does. It’s just another one of them contraptions that keep the world movin’.

Chemical feed pumps, chemical dosing pumps, whatever you wanna call ’em, they’re a necessary part of this modern life of our. Just doin’ their job, day in and day out, and not complainin’ neither. That’s more than ya can say about some people.

Tags: [Chemical Feed Pump, Chemical Dosing Pump, Industrial Pump, Positive Displacement Pump, Water Treatment, Chemical Industry, Food Industry, Sodium Hypochlorite, Self-Priming Pump]