Alright, so today I wanna talk about magnetic drive pumps, based on something I actually messed around with last week. It was a bit of a headache, but figured I’d share how it went down.

The Setup

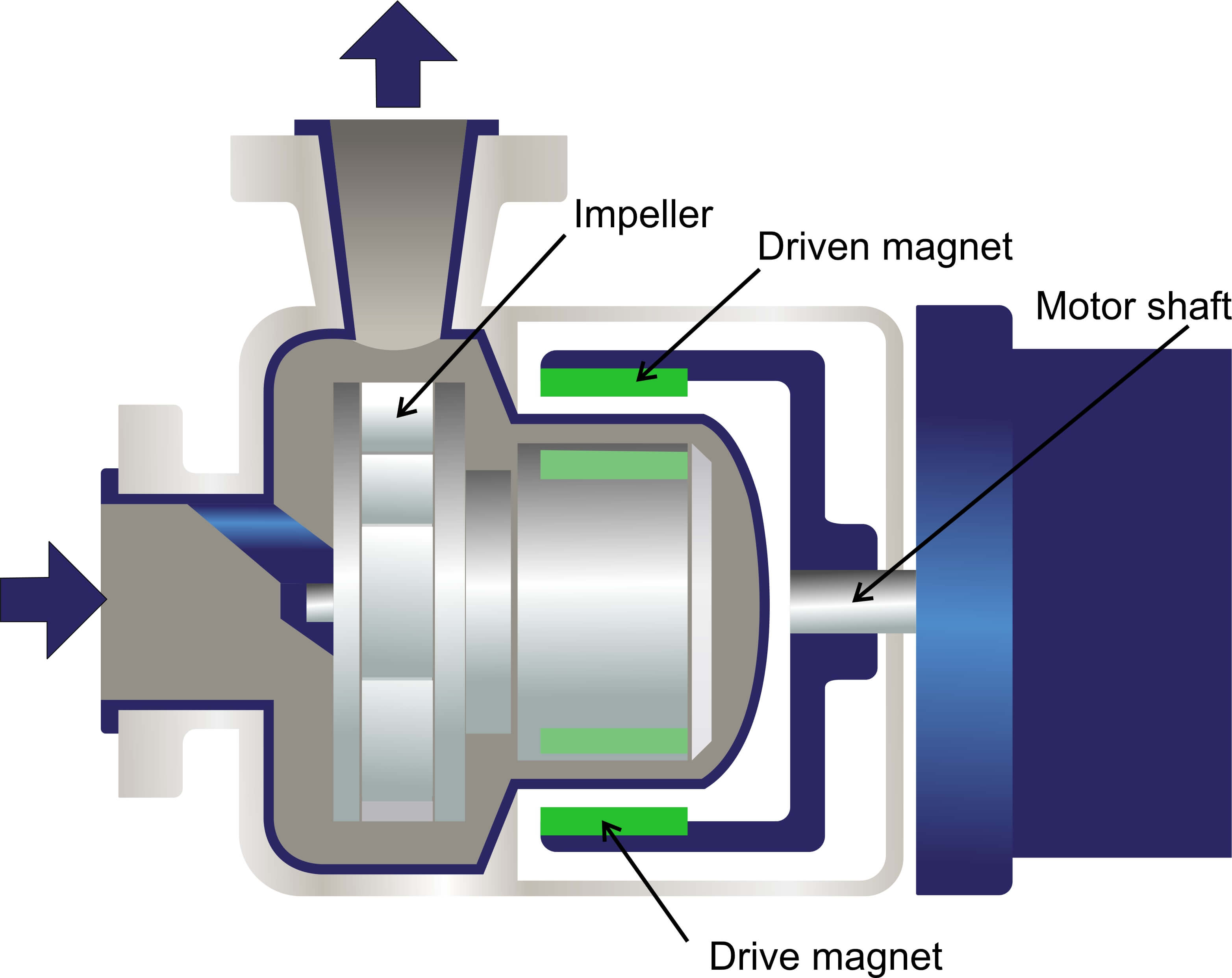

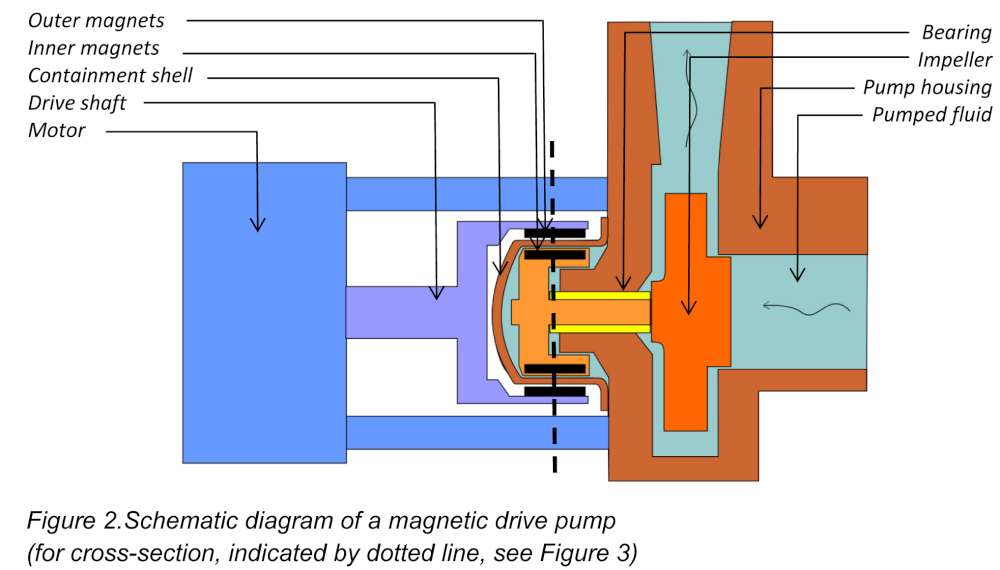

So, the basic idea with these pumps is that you’ve got a motor that spins a set of magnets. These magnets then drive another set of magnets attached to an impeller inside the pump housing. No direct shaft connection, hence, “magnetic drive.” I got hold of one for a little project involving circulating some… well, let’s just say ‘special’ liquids in a closed loop.

Getting Started – The Theory (Kind Of)

I started out like everyone else – googling. Wanted to be sure I understood the core principle. Basically, you’ve got the motor turning the external magnet assembly. That external magnet spins because, well, the motor’s doing its thing. That spinning external magnet creates a rotating magnetic field. The internal magnet assembly, connected to the impeller, is then dragged along by that magnetic field, which then makes the impeller spin and pump the fluid.

The Disassembly

The pump I got was used, and a bit crusty. First thing I did? Tore it apart. Noticed right away that the inner magnet assembly was caked with some sort of residue. Spent a good hour cleaning it with some solvent. The magnets themselves looked okay, no visible cracks or anything. I guess I was just hoping to find something broken so I can quickly determine what’s wrong. No luck.

The “Oh Crap” Moment

Reassembled the pump, hooked it up, and… barely any flow. The motor was spinning, I could hear the impeller kinda trying to spin, but it wasn’t moving fluid like it should. I was like, “oh crap, this thing is busted.” Started doubting everything. Is it a motor problem? Is it an impeller problem? or is it something I did when cleaning it?

Troubleshooting Round 1: Checking the Motor

First thought: is the motor even strong enough? Disconnected the magnet assembly and ran the motor on its own. Seemed fine, spun up to speed no problem. Ruled out the motor as the primary issue, at least.

Troubleshooting Round 2: The Magnet Gap

Next, I started focusing on the magnetic coupling itself. I remembered reading something about the gap between the magnets being critical. If the gap’s too big, the magnetic field can’t effectively transfer the torque. So, I took a closer look at the pump housing. There were shims that determined how close the two magnet assemblies were to each other. I removed one of the shims to reduce the gap. Reassembled. Still nothing.

Troubleshooting Round 3: The Blockage Hunt

Frustrated, I figured maybe there’s a blockage somewhere in the pump. Took the whole thing apart again. Checked the inlet and outlet ports, poked around with a wire. Found some tiny bits of debris, but nothing major. Cleaned everything meticulously, reassembled… and still nothing!

The Breakthrough: Air Lock

I was about to throw the pump against the wall, when it suddenly hit me. Air! The whole loop system wasn’t properly primed, and there was probably a massive airlock inside the pump housing. I tried tilting the pump at different angles while it was running, and BAM, suddenly the impeller caught, and the fluid started flowing.

The Lessons Learned

- Air locks are the devil: Seriously, always prime your system properly before running a magnetic drive pump.

- Gap matters: Make sure your magnet gap is within spec. Too big, and you’ll lose coupling.

- Cleanliness is key: Debris can wreck havoc on these pumps. Keep things clean.

- Don’t give up too easily: Sometimes it’s the simplest thing that’s causing the problem.

Final Thoughts

Magnetic drive pumps are pretty neat, but they can be a pain in the butt to troubleshoot. Hope this little write-up helps someone out there avoid the same headaches I had. Now, time for a beer.