Today, I messed around with a magnetic drive pump head. I’ve been meaning to get a better understanding of how these things work, so I finally took one apart.

First, I grabbed the pump head from my old, broken pump. It was just sitting in the garage, gathering dust. I figured, “Why not take a crack at it?”

Disassembly Time

I started by unscrewing the main casing. It was pretty straightforward, just a few screws holding it together.

Then to avoid breaking anything during disassembly, I looked carefully to see how it was structured.

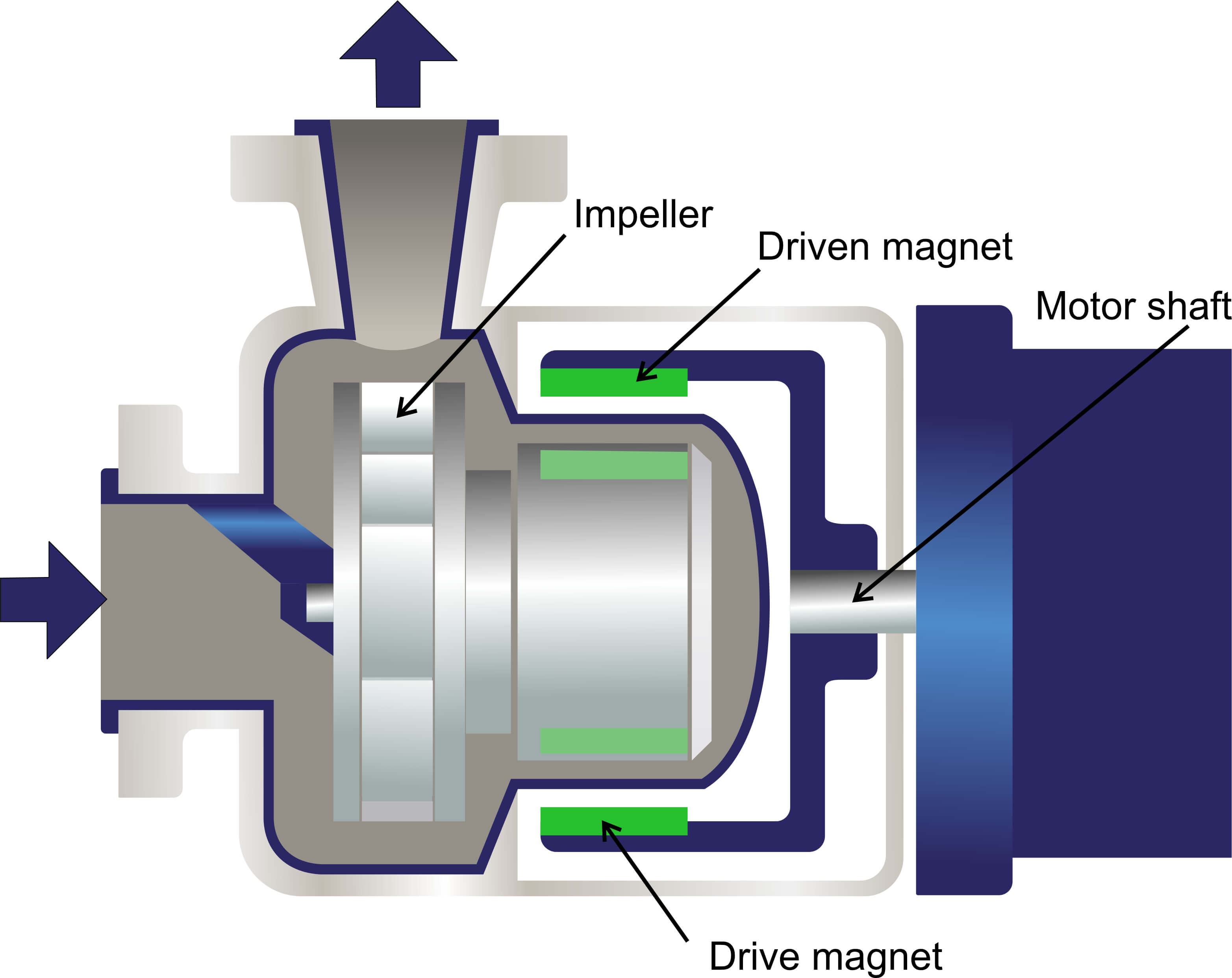

- I noticed there were no direct connections between the motor and the impeller (the part that spins to move the liquid). That’s the whole point of a magnetic drive, right? No direct shaft, no seals to leak.

- I pulled off the impeller housing, and there it was – the impeller with its magnets, all neatly arranged.

- Then, I removed the drive magnet assembly, which is the part connected to the motor. It had a bunch of magnets too, arranged in a circle.

It’s pretty cool how it works. The motor spins the drive magnet, and the magnetic force pulls the impeller along, making it spin and pump the liquid. All without any physical connection! That’s neat.

Putting It Back Together

After I’d poked around and satisfied my curiosity, I put the whole thing back together. It’s always a bit of a gamble to see if you can reassemble something after taking it apart, but I managed it without any leftover parts!

It’s pretty important.

I screwed everything back tight, making sure it was all lined up. I haven’t tested it to see if it still would work (since the pump motor itself is busted), but at least I know how the pump head itself functions now. I feel pretty good about finally tackling that little project.