Okay, so I’ve been messing around with pumps in my workshop lately, and I wanted to share my experience with this thing called a “magnetic drive positive displacement pump.” It sounded fancy, and honestly, I was a little intimidated at first, but it turned out to be pretty cool.

Getting Started

First, I got my hands on one of these pumps. I didn’t buy a brand new one; I found a used one online that looked like it was in decent shape. I figured I could take it apart, see how it works, and maybe even fix it up if needed. That’s half the fun, right?

Taking It Apart

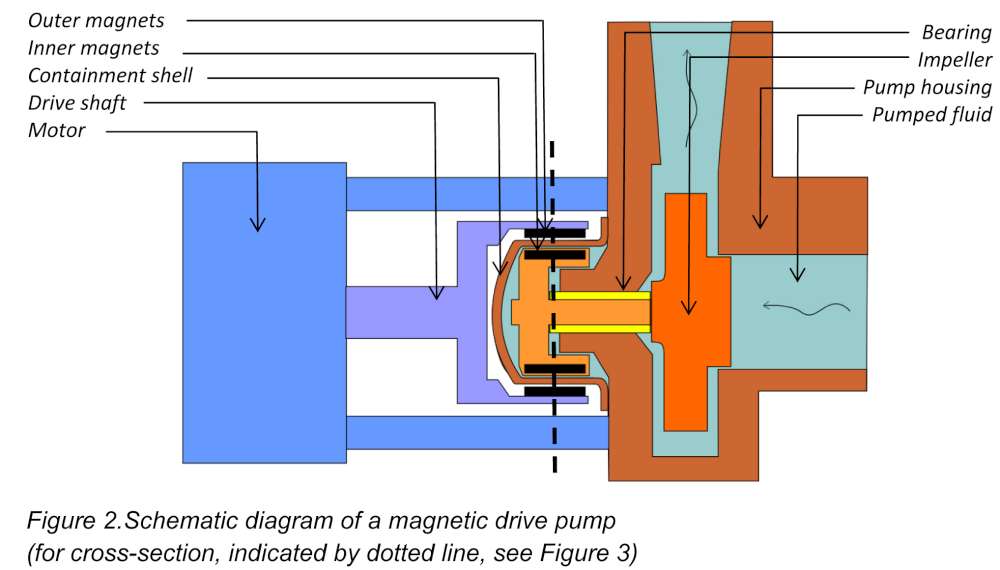

Next, I laid out all my tools – wrenches, screwdrivers, the whole nine yards. I started by carefully removing the outer casing. I took my time because I didn’t want to break anything. Inside, I saw the impeller and the magnets. It’s pretty neat how it’s all sealed up; there’s no direct connection between the motor and the pump chamber, which means no leaks! That’s a big plus, especially if you’re dealing with, I dunno, nasty chemicals or something.

Figuring Out How It Works

The basic idea is that the motor spins a set of magnets on the outside, and these magnets make another set of magnets inside the pump chamber spin, too. This inner set is attached to the impeller, which pushes the fluid through the pump. Since it’s a positive displacement pump, it moves a fixed amount of fluid with each rotation. It’s not like those centrifugal pumps that just kind of fling the fluid around.

- Disassemble the pump very carefully.

- Identify the parts: outer magnets, inner magnets, impeller, casing.

- Observe the sealed design: no direct shaft connection, so no leaks!

Putting It Back Together

After I cleaned everything up and made sure there were no cracks or anything, I put the pump back together. I followed the reverse order of how I took it apart, making sure all the screws were tight. It’s a little bit like a puzzle, but not too complicated.

Testing It Out

Finally, I hooked the pump up to some tubing and a power source. I used water for testing – no need to waste anything fancy. I flipped the switch, and it started humming. And… it worked! Water started flowing through the tubing, nice and steady. It was pretty satisfying to see it all come together.

It might seems a little bit complex, but it is very funny to do and I did it!