Okay, let’s talk about moving sulfuric acid. Had a job recently where we needed to transfer a decent amount from a larger container to smaller ones. You can’t just tip this stuff, obviously, so a pump was the only way.

Figuring Out the Pump Situation

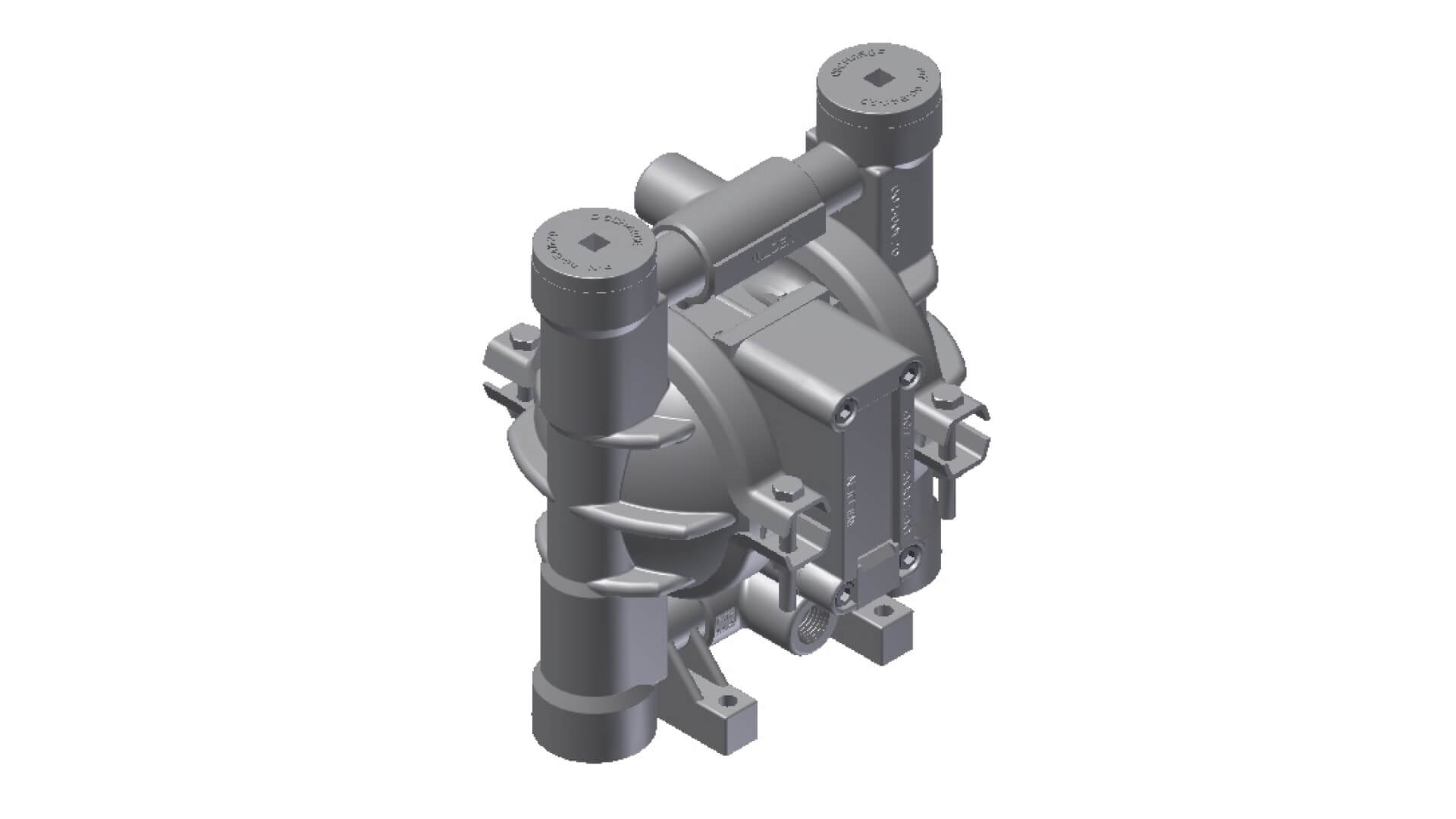

First thing was getting the right pump. You hear stories, right? Using the wrong kind of pump for strong acids… yeah, not pretty. Didn’t want a repeat of that one time with the leaky fitting – still remember that mess. So, I spent a good chunk of time looking at options. Needed something chemically resistant, definitely. PTFE or PVDF linings, that sort of thing. Didn’t need anything massive, just reliable.

Ended up picking one that seemed like a good balance. Not the cheapest, not the fanciest. Looked solid enough when it arrived. Heavy little thing.

Getting It All Set Up

Unboxing and setup. Always feels like the instructions are written by someone who’s never actually done it in the field. Took me a bit to get the hoses connected just right. You really gotta crank down on those fittings, but not too much, or you risk cracking something. Found that sweet spot after a few tries. Made sure the suction line reached the bottom of the main drum and the discharge line was securely placed in the receiving container.

- Checked all seals one more time.

- Made sure the power cord wasn’t anywhere it could get splashed.

- Positioned myself so I could hit the off switch fast if needed.

Safety gear first, always. Face shield, thick gloves, apron. Feeling like a spaceman, but better safe than sorry with this stuff. Had the neutralizer and spill kit right there, ready to go. You hope you don’t need it, but you prepare like you will.

The Actual Transfer Process

Alright, moment of truth. Flipped the switch. The pump kicked on with a low hum. Watched the clear suction hose like a hawk. Saw the acid start moving up… good sign. Flow seemed steady. It wasn’t super fast, which was actually fine by me. Gave me more time to react if something went sideways.

Just stood there, watching it fill the smaller container. Listened to the pump motor. Any change in sound, you pay attention. It droned on pretty consistently, though. Moved the discharge hose to the next container, then the next. Just a repetitive process. Tedious, but focused. You can’t let your mind wander too much doing this.

Wrapping It Up

Once the last container was filled, switched off the pump immediately. Disconnecting requires care too, there’s always a bit left in the lines. Drained the hoses as best I could back into the source drum before carefully taking everything apart. Rinsed the pump externally according to the (slightly vague) instructions. Didn’t want any residue left on it.

Overall? It worked. The pump did what it was supposed to do. No leaks, no spills, no drama. That’s a win in my book when dealing with sulfuric acid. It wasn’t exciting, just a job that needed doing carefully. Got it done, packed up, moved on to the next thing. Just glad that part of the day was over.