Alright, so today I wanna share my experience comparing magnetic drive pumps and centrifugal pumps. It was a real hands-on kinda thing, not just some textbook comparison, ya know?

The Setup

First off, I needed a project. A real-world application where I could actually see the difference between these two types of pumps. I landed on a simple water circulation system – nothing fancy, just moving water from a tank to a higher point and back down. I grabbed both a small magnetic drive pump and a similarly sized centrifugal pump. Got all the piping, valves, and fittings I needed.

Centrifugal Pump: The Old Reliable

- Getting Started: Hooked up the centrifugal pump first. Pretty straightforward. Inlet hose went to the tank, outlet hose went up to my designated “high point”. Plugged it in, and boom, water started flowing.

- The Flow: It did what it was supposed to do. Decent flow rate, not too noisy. I started playing with the valves to simulate different load conditions – throttling the flow, partially blocking the outlet, that kinda stuff.

- Observations: What I noticed was, as I restricted the flow, the pump started to whine a bit more. And when I completely blocked the outlet (briefly, of course, didn’t wanna burn it out), the motor was definitely working harder.

Magnetic Drive Pump: The Seal-less Wonder

- Installation: Swapped out the centrifugal pump for the magnetic drive one. Wiring was similar, so that was easy.

- Initial Run: Fired it up. Noticed right away it was a bit quieter than the centrifugal pump. The flow rate seemed comparable, maybe slightly less.

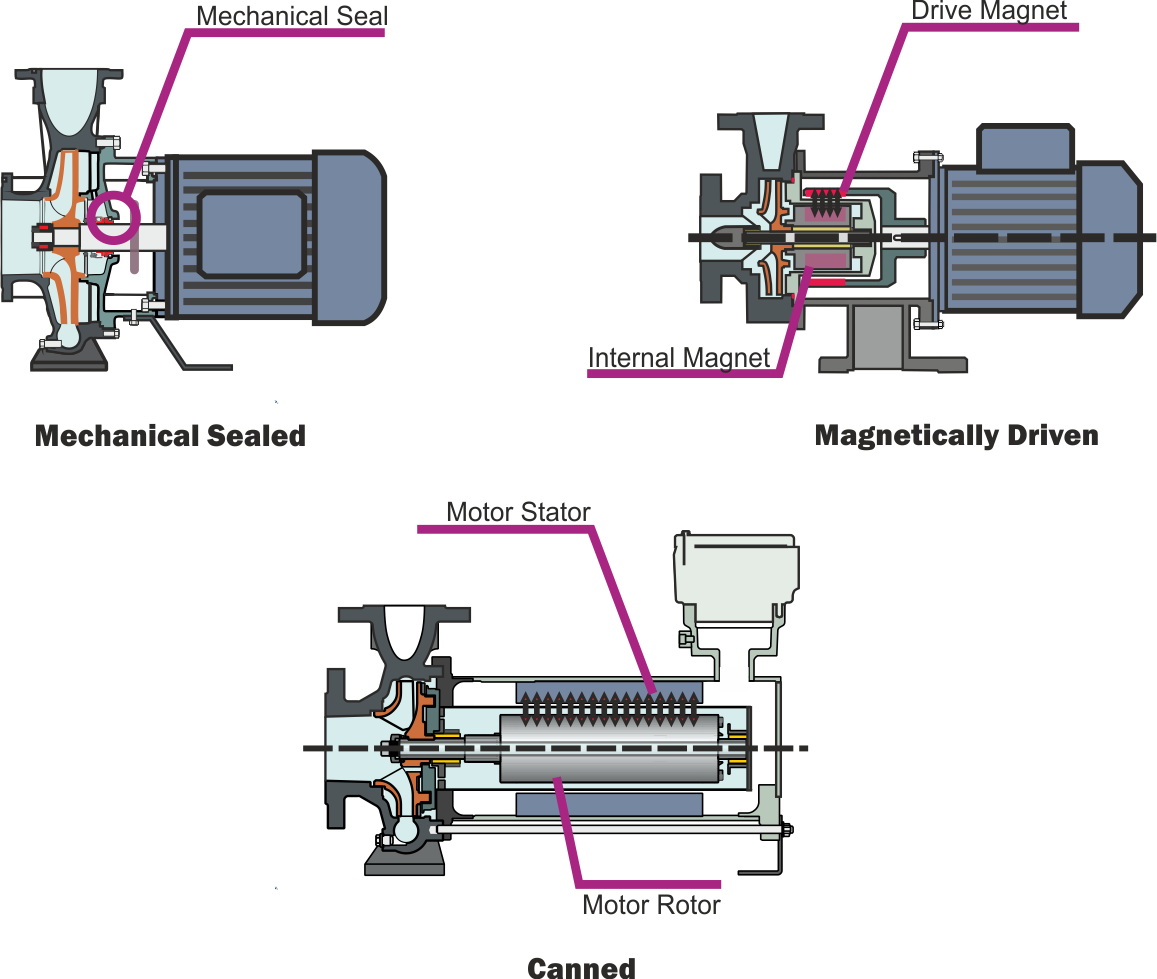

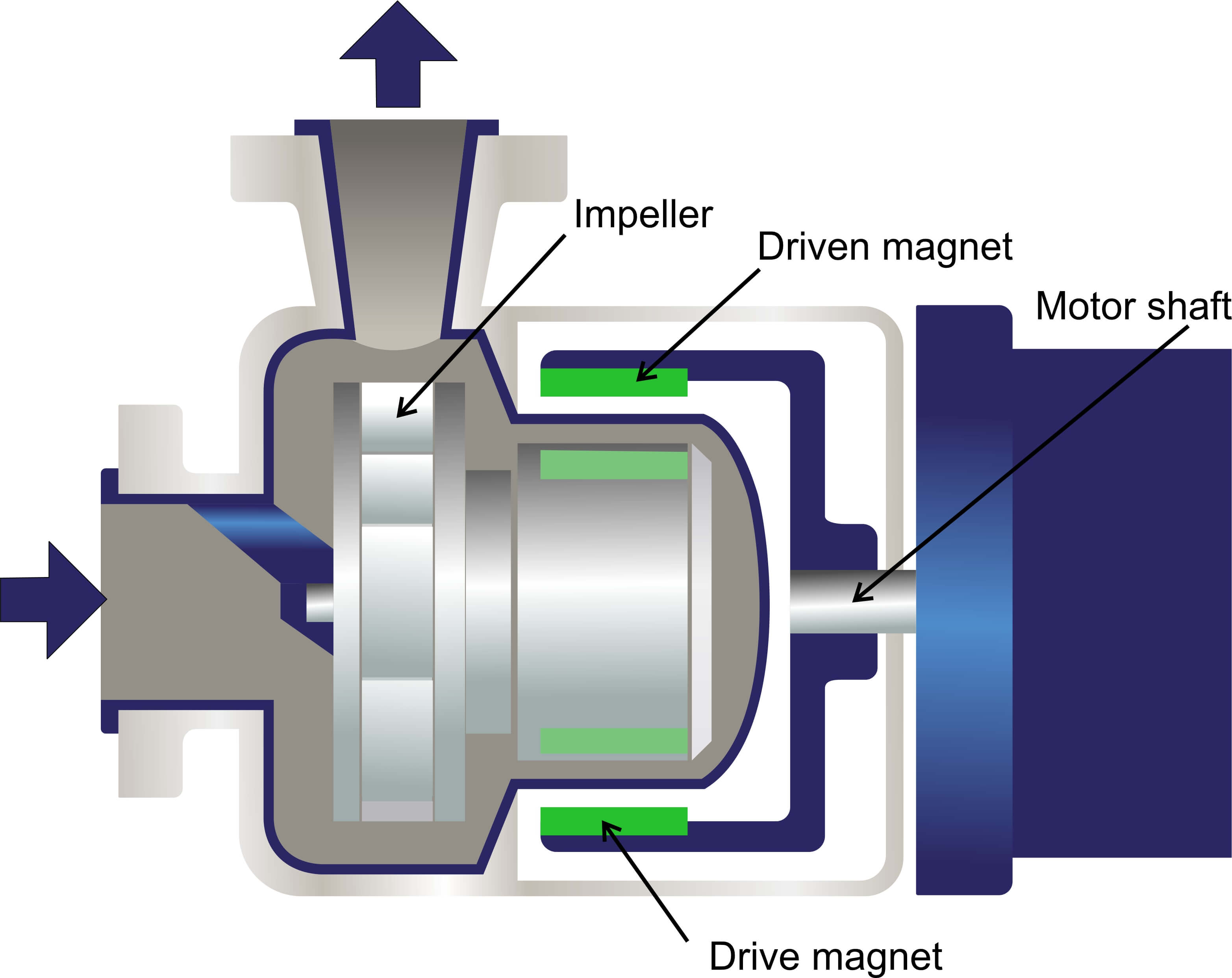

- Stress Test: I did the same throttling experiment as before. Here’s where things got interesting. As I restricted the flow, the magnetic drive pump seemed to handle it better. No noticeable whining, and it didn’t sound like it was straining as much. And when I blocked the outlet, the pump just kinda… stopped pumping. The motor was still running, but the magnetic coupling was slipping, preventing any damage. That’s the big advantage of these pumps – no mechanical seal to wear out or leak!

The Tear-Down

After a few hours of running each pump under different conditions, I took ’em apart (carefully, of course). The centrifugal pump looked pretty much as expected. Impeller was a little worn, but nothing major. The magnetic drive pump was interesting. The impeller assembly was completely separated from the motor. Just a magnetic coupling doing all the work. Pretty slick.

What I Learned

Here’s the takeaway

- Centrifugal Pumps: These are workhorses. They can move a lot of fluid, and they’re relatively inexpensive. But they’re not great at handling restrictions in flow, and the mechanical seal is a potential point of failure.

- Magnetic Drive Pumps: More expensive, but they’re much better at handling flow restrictions. The seal-less design means less maintenance and less risk of leaks, especially important if you’re pumping nasty stuff.

My Conclusion

For my simple water circulation project, either pump would work fine. But if I were dealing with corrosive chemicals, or if I needed a pump that could handle frequent starts and stops without wearing out, I’d definitely go with the magnetic drive pump. It’s all about choosing the right tool for the job, ya know?

Hope this helps someone out there. Happy pumping!