Okay, here’s my attempt at a blog post about dealing with magnetic drive pump problems, based on a recent experience.

Alright folks, gather ’round! Today I’m gonna spill the beans on a headache I had with a magnetic drive pump. You know, those sealless wonders that are supposed to be all reliable and low-maintenance? Yeah, well, reality hit me hard recently.

It all started a couple weeks ago. We’ve got this magnetic drive pump that’s crucial for circulating coolant in one of our systems. One morning, I walk in, and the whole system is running hotter than usual. First thing I did was to check the pump.

I got closer and heard this god-awful grinding noise coming from the pump housing. Not good, right? Immediately shut the thing down, naturally.

So, began the troubleshooting. First things first, I wanted to rule out the obvious. Checked the power supply – was it getting juice? Yep, voltage was fine. Next, the motor itself. Gave it a spin by hand (after disconnecting the power, obviously!) – felt a little stiff, but nothing too alarming.

Then I had to tear into the pump itself. Now, I’ve worked on these things before, so I felt reasonably confident. Drained the coolant, disconnected the piping, and hauled the pump over to my workbench.

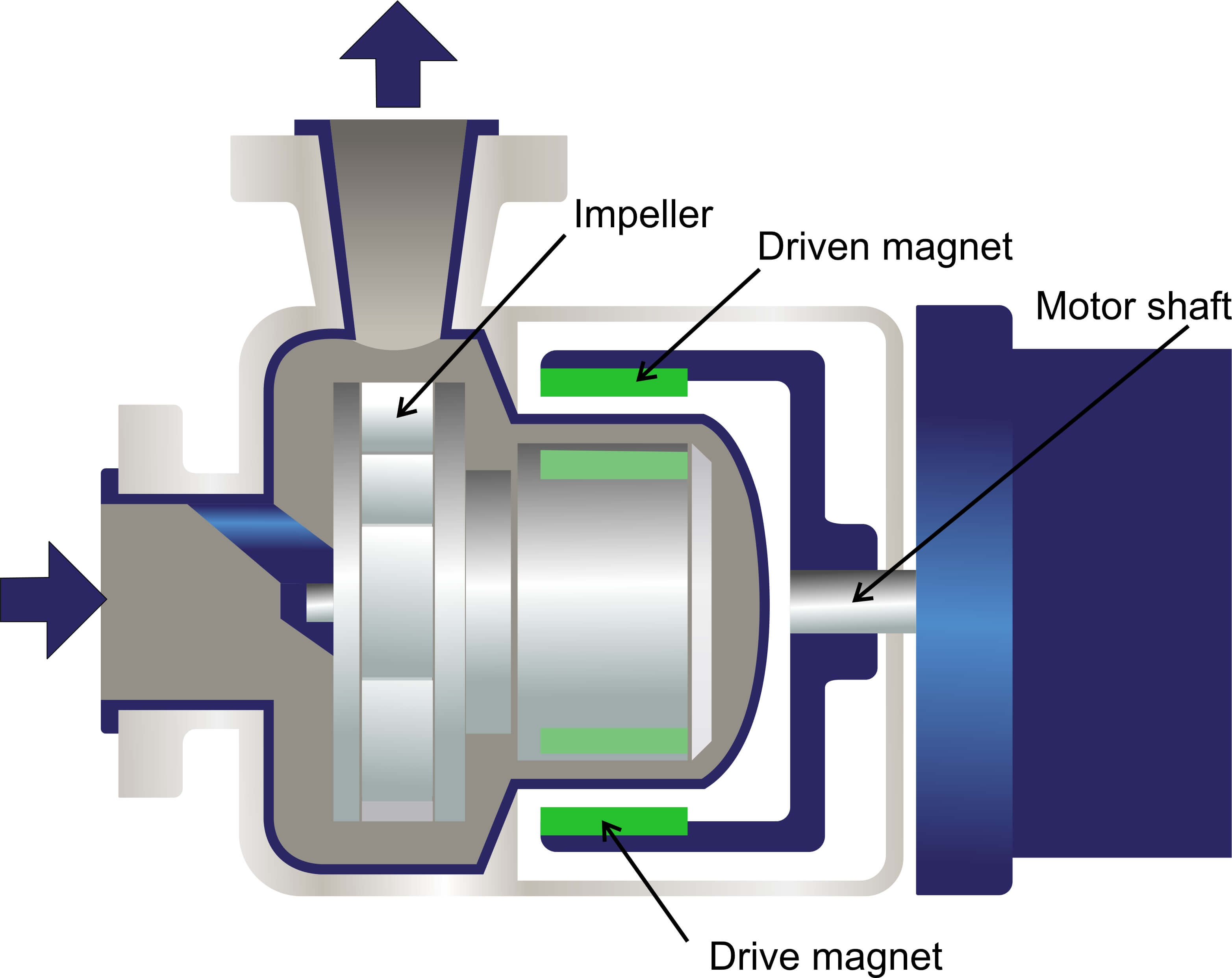

Started by taking off the back cover. Inside, you’ve got your impeller, driven by magnets that couple to the motor. Gave the impeller a spin – and that’s when I found the culprit! It was really hard to turn and I could feel a lot of resistance.

I carefully removed the impeller assembly, and there it was: debris! Small bits of what looked like scale and other particulate matter were jammed in between the impeller and the pump housing. That’s what was causing the grinding and the resistance, and ultimately leading to the pump not circulating properly.

Here’s where it gets fun:

- Cleaning Time: I spent a good hour meticulously cleaning every nook and cranny of the impeller and the pump housing. Used a soft brush, some solvent, and a whole lotta patience.

- Inspection: Once everything was clean, I gave it all a good once-over. Checked for any signs of wear or damage to the impeller, the magnets, or the bearings. Thankfully, everything looked okay.

- Reassembly: Put everything back together carefully, making sure all the o-rings and seals were properly seated. Added some fresh coolant to the system.

Flipped the switch, held my breath, and… purred like a kitten! The grinding noise was gone, and the coolant was flowing smoothly. The system temperature went back down to normal within minutes.

Lesson Learned? Even “low-maintenance” equipment needs regular check-ups. In this case, better filtration of the coolant would probably prevent this from happening again. I’m now scheduling routine inspections of this pump as well.

So yeah, that was my recent adventure with a magnetic drive pump. Hope this helps someone out there avoid a similar headache!