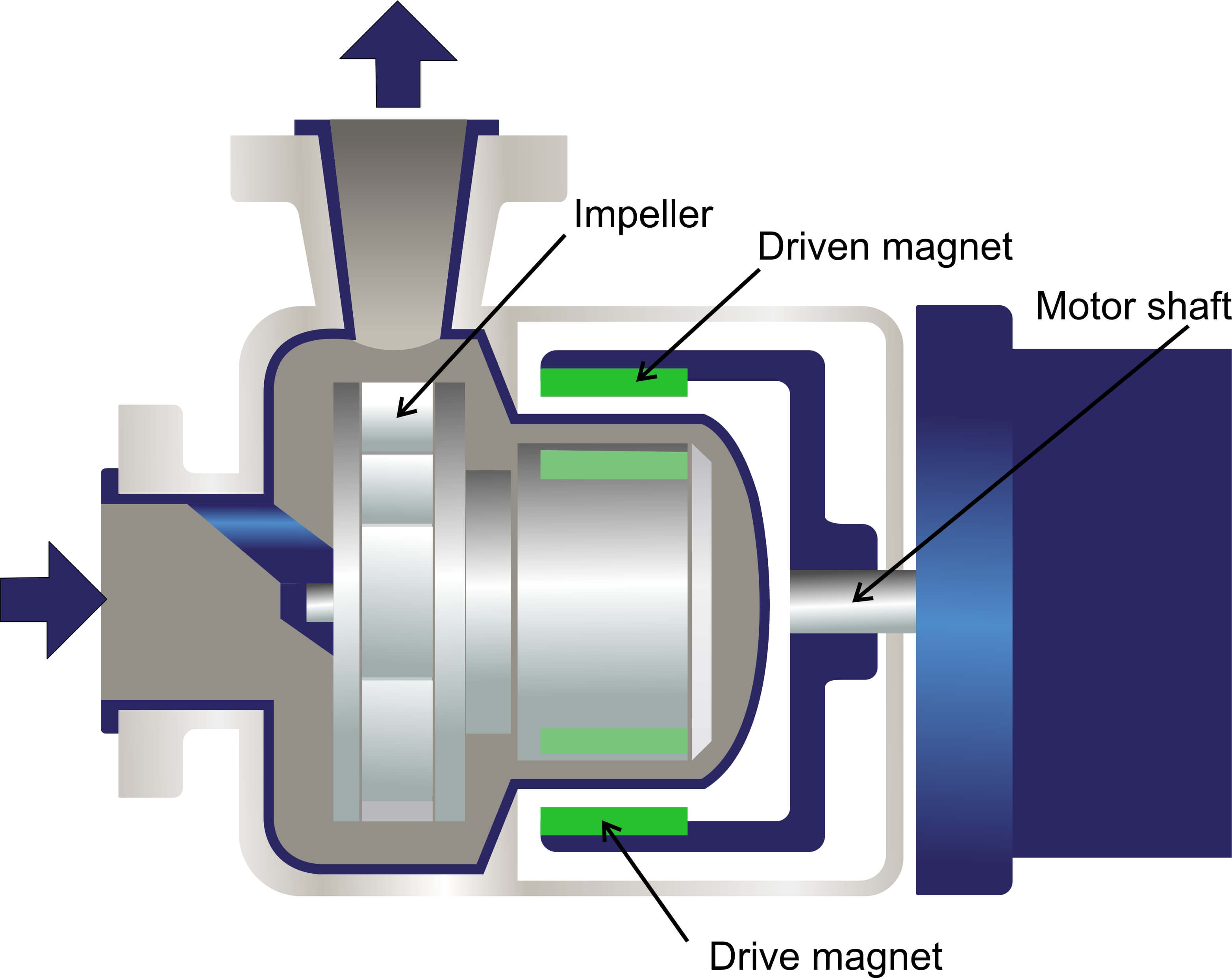

Okay, so the other day, I needed to move some liquid around in this project I was working on. I didn’t want any leaks, and a regular pump with seals just seemed like a future headache. That’s when I remembered these things called magnetic drive circulation pumps. Basically, the motor and the pump impeller are separated, and the power is transferred using magnets. No seals, no leaks, sounds pretty neat, right?

Getting Started

First, I picked out a pump that seemed like it would fit the bill. I needed something that could handle the viscosity of the liquid I was using, and also had the right flow rate. There are tons of options out there, so it took a little digging to find the right one. I made sure to choose the right size and capacity for what I required.

Setting It Up

Once I had the pump, it was time to get it all hooked up. This was surprisingly easy. I just connected the inlet and outlet tubing. With magnetic pumps, there is no need to align the shaft and it’s super convenient.

- Connected inlet tubing to the liquid source.

- Attached outlet tubing to where I needed the liquid to go.

- Double-checked all the connections to make sure everything was snug.

Powering It On

Next, I plugged it in and flipped the switch. I was a little nervous, hoping I wouldn’t see any leaks or hear any weird noises. But, it started humming along nicely. The liquid started flowing, and there wasn’t a single drop anywhere it shouldn’t be. Success!

Watching It Work

I let it run for a while, just to make sure everything was working as expected. I kept an eye on the flow rate and listened for any changes in the pump’s sound. After a good bit of time, I was satisfied that it was doing its job perfectly.

Overrall, I have to say, using a magnetic drive circulation pump was a great *’s simple to set up, works great, and most importantly, it won’t fail in the future.